Ruida | Innovative Copper Key Equipment for Advanced Manufacturing Solutions

Transforming Manufacturing Excellence with Advanced Copper Key Equipment

In today's rapidly evolving manufacturing landscape, copper key equipment has emerged as a transformative force in the production of copper pipe fittings and related components. This advanced technology represents a significant leap forward in manufacturing capabilities, offering solutions that combine precision, efficiency, and sustainability.

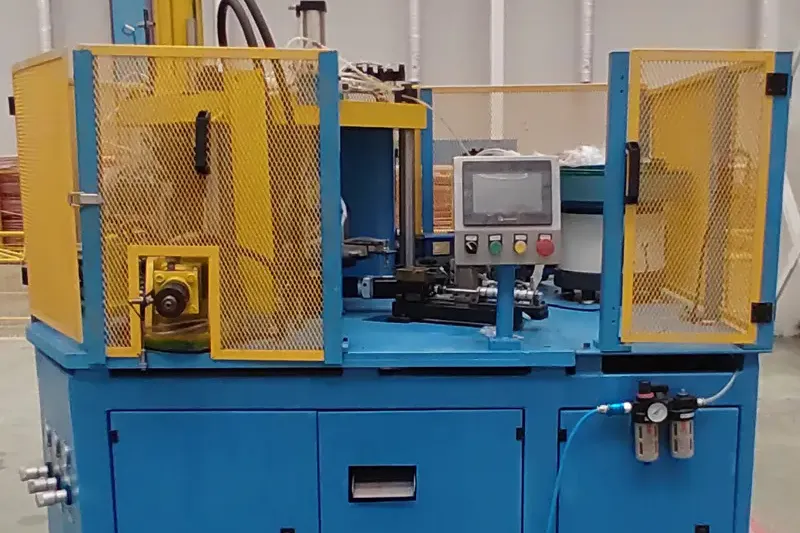

Modern copper key equipment brings revolutionary changes to traditional manufacturing processes. These systems incorporate advanced hydraulic press technology and sophisticated control mechanisms, ensuring exceptional quality in every production cycle. The equipment's intelligent design allows for seamless adaptation to various manufacturing requirements, making it an invaluable asset for companies seeking to maintain competitive advantages in the global market.

What sets contemporary copper key equipment apart is its remarkable versatility across different industrial applications. In the HVAC sector, these systems produce essential components for air conditioning and refrigeration systems. The plumbing industry relies on this equipment to manufacture high-quality pipe fittings that meet stringent industry standards. Industrial applications benefit from the equipment's ability to produce precise, durable components for various specialized needs.

The innovation in copper key equipment extends beyond basic manufacturing capabilities. These systems incorporate smart manufacturing principles that enhance overall operational efficiency. The integration of automation technology ensures consistent quality while significantly reducing the likelihood of human error. Advanced monitoring systems continuously oversee the production process, maintaining optimal performance and ensuring each component meets exact specifications.

Environmental consciousness plays a crucial role in modern copper key equipment design. These systems employ energy-efficient technologies that significantly reduce power consumption compared to conventional manufacturing methods. The equipment's precise operation minimizes material waste, while advanced material handling systems ensure efficient resource utilization. This commitment to sustainability not only benefits the environment but also contributes to reduced operational costs.

Looking toward the future, copper key equipment continues to evolve with emerging technologies. The integration of smart manufacturing capabilities allows for enhanced production monitoring and control. These advancements enable manufacturers to maintain higher quality standards while improving operational efficiency. The equipment's adaptability ensures it can meet changing industry demands while maintaining exceptional performance standards.

Safety and ergonomics remain paramount in modern copper key equipment design. Advanced safety features protect operators while maintaining productive workflows. The equipment's user-friendly design reduces operator fatigue and enhances overall workplace safety, creating an environment that promotes both productivity and worker well-being.