Ruida | Advanced Copper Tube Hydraulic Press Systems for Precision Manufacturing

Advancing Industrial Excellence: The Impact of Copper Tube Hydraulic Press Technology

In today's rapidly evolving manufacturing landscape, copper tube hydraulic press technology represents a cornerstone of precision engineering and production efficiency. This sophisticated technology has transformed the way industries approach copper component manufacturing, setting new standards for quality and productivity.

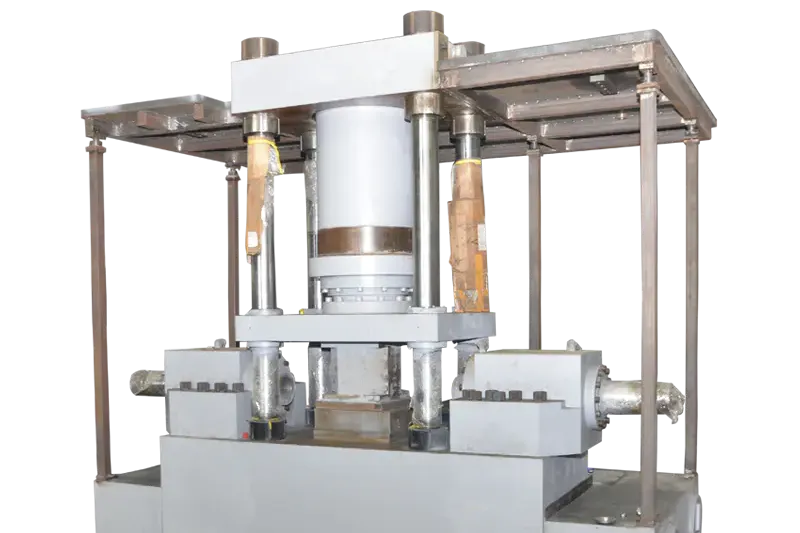

Core Technology Overview

Modern copper tube hydraulic press systems combine robust mechanical capabilities with advanced digital control systems. These machines utilize sophisticated hydraulic mechanisms that deliver consistent forming pressure while maintaining precise dimensional control throughout the production process. The integration of smart control systems ensures that each operation achieves optimal results, making these machines indispensable in contemporary manufacturing environments.

Applications Across Industries

The versatility of copper tube hydraulic press technology extends throughout various industrial sectors. In HVAC manufacturing, these systems excel in producing components that demand exact specifications for efficient thermal transfer and system reliability. The plumbing industry relies on this technology for creating high-quality fittings that ensure leak-free connections. Additionally, specialized industrial applications benefit from the precise forming capabilities these machines offer.

Quality Control Innovation

Modern copper tube hydraulic press systems incorporate comprehensive monitoring capabilities that ensure consistent product quality. Advanced sensor arrays track critical parameters throughout the forming process, while integrated quality control systems provide:

- Continuous dimensional verification

- Real-time process monitoring

- Automated quality documentation

- Precise tolerance management

Manufacturing Efficiency

The evolution of hydraulic press technology has brought significant improvements in manufacturing efficiency. These systems feature sophisticated automation that streamlines production while maintaining exact quality standards. The reduction in manual intervention not only increases productivity but also enhances workplace safety, creating an environment that promotes both efficiency and operator well-being.

Sustainable Manufacturing

Environmental consciousness plays an increasingly important role in modern hydraulic press design. These systems optimize resource utilization through precise control mechanisms, significantly reducing material waste. The equipment's energy-efficient operation aligns with contemporary environmental standards while helping manufacturers reduce their operational costs and environmental impact.

Future Developments

Looking ahead, copper tube hydraulic press technology continues to evolve with emerging manufacturing trends. The integration of smart manufacturing capabilities enables enhanced production monitoring and control. These advancements ensure manufacturers can maintain higher quality standards while improving operational efficiency, positioning them for success in an increasingly competitive market.